The mechanical/Destructive test (DT) required for welding procedure -WPS/PQR

According to ASME SECTION-IX, before starting the work need to be the qualification of the procedure that is welding procedure specification (WPS) and procedure qualification record (PQR). Click for more about WPS and their process And after successful completion of the welding of the test coupon. test piece coupon sends to the laboratory for mechanical or destructive testing. test perform as per ASME code requirement that is given below;

Table QW-451.1

Mechanical tests required for procedure qualification

|

Mechanical test

|

NOTES:

Note 1, 2, 3, and 4, see below link

(5) Four side‐bend tests may be substituted for the required face‐ and root‐bend tests, when thickness T is 10 mm and over

(6) For test coupons over 150 mm thick, the full thickness of the test coupon shall be welded.

Explanation:-

1. If the welder qualified Welding procedure specification (WPS), below the thickness of 1.5 mm of a test piece, it means the welder qualifies for minimum thickness T, and maximum thickness 2T and their maximum deposited weld metal thickness shall be 2t. And the test required for under this thickness limit is 2 tension, 2 face bend, and 2 root bend, and there is no required test for side bend.

2. If the welder qualified Welding procedure specification (WPS), in between 1.5 to 10 mm thickness of the test piece, it means the welder qualifies for a minimum thickness of 1.5mm, and maximum thickness 2T and their maximum deposited weld metal thickness shall be 2t. And the test required for under this thickness limit is 2 tension, 2 face bend, and 2 root bend, and for the side bend test see note 5.

3. If the welder qualified Welding procedure specification (WPS), in between over 10 but less than 19 mm thickness of the test piece, it means the welder qualifies for a minimum thickness of 5mm, and the maximum thickness 2T and their maximum deposited weld metal thickness shall be 2t. Under this thickness limit, the destructive test required 2 tension, 2 face bend, and 2 root bend, and for the side bend test see note 5.

4. If the welder qualified Welding procedure specification (WPS), in between 19 to less than 38mm thickness of the test piece, it means the welder qualify for a minimum thickness 5mm, and maximum thickness 2T and their maximum deposited weld metal thickness shall be 2t when deposited weld metal thickness less than 19 mm (when t <19). Under this thickness limit, the destructive test required 2 tension tests with a note 4, 4 side bend test, and there is no required of the face bend test and root bend test.

5. If the welder qualified Welding procedure specification (WPS), in between 19 to less than 38mm thickness of the test piece, it means the welder qualify for minimum thickness 5mm, and maximum thickness 2T and their maximum deposited weld metal thickness shall be 2T when deposited weld metal thickness greater than equal to 19 mm (when t ≥ 19). Under this thickness limit, the destructive test required 2 tension tests with a note 4, 4 side bend test, and there is no required face bend test and root bend test.

6. If the welder qualified Welding procedure specification (WPS), in between 38 to 150mm thickness of the test piece, it means the welder qualify for a minimum thickness 5mm, and maximum thickness 200, and their maximum deposited weld metal thickness shall be 2t when deposited weld metal thickness less than 19 mm (when t < 19). For more details see note 3. Under this thickness limit, the destructive test required 2 tension tests with a note 4, 4 side bend test, and there is no required face bend test and root bend test.

7. If the welder qualified Welding procedure specification (WPS), in between 38mm to 150mm thickness of the test piece, it means the welder qualify for a minimum thickness 5mm, and maximum thickness 200, and their maximum deposited weld metal thickness shall be 200 when deposited weld metal thickness greater than equal to 19 mm (when t ≥ 19). For more details see note 3. Under this thickness limit, the destructive test required 2 tension tests with a note 4, 4 side bend test, and there is no required of the face bend test and root bend test.

8. If the welder qualified Welding procedure specification (WPS), over 150mm thickness of the test piece, it means the welder qualify for a minimum thickness of 5mm, and maximum thickness 1.33T and their maximum deposited weld metal thickness shall be 2t when deposited weld metal thickness less than 19 mm (when t < 19). For more details see note 3. Under this thickness limit, the destructive test required 2 tension tests with a note 4, 4 side bend test, and there is no required face bend test and root bend test.

9. If the welder qualified Welding procedure specification (WPS), over 150mm thickness of the test piece, it means the welder qualify for minimum thickness 5mm, and maximum thickness 1.33T and their maximum deposited weld metal thickness shall be 1.33t when deposited weld metal thickness greater than equal to 19 mm (when t ≥ 19). For more details see note 3. Under this thickness limit, the destructive test required 2 tension tests with a note 4, 4 side bend test, and there is no required test of the face bend test and root bend test.

Tension tests according

SPECIMENS

Tension test specimens shall conform to one of the types illustrated in Figures QW-462.1(a) through QW-462.1(e) and shall meet the requirements of QW-153 (given below).

|

| Mechanical tests required for making WPS/PQR |

Reduced Section for Plate QW-151.1

Reduced plate test section specimens conforming to the requirements shown in Figure QW-462.1(a) may be used for tension tests on all thicknesses of the plate.

(a) For thicknesses up to and including 25 mm, the full thickness specimen shall be used for each required tension test specimen.

(b) For plate thickness greater than 25 mm, full-thickness specimens or multiple specimens may be used, provided(c) and (d) are complied with.

(c) When multiple specimens are used, in place of full-thickness specimens, each set shall represent a single tension test of the full plate thickness. Closely, all the specimens required to represent the full thicknesses of the weld at one location shall comprise a set.

(d) When multiple test specimens are necessary the entire thickness shall be mechanically cut into a minimum number of approximately equal strips of a size that can be tested in the available testing equipment. Each specimen of the set shall be tested according to code requirements and meet the requirements of table QW-153.

QW-151.2 Reduced Section for the pipe.

Reduced section specimens conforming to the requirements given in Figure ASME SEC-IX QW-462.1(b) it may be used for tension tests on all thicknesses of pipe having an outside diameter greater than 75 mm.

(a) For thicknesses up to and including 25 mm, the full-thickness specimens shall be used for each required tension tests.

(b) For the pipe thicknesses greater than 25 mm, full-thickness specimens or multiple specimens may be used, provided in (c) and (d) are complied with.

(c) When multiple specimens are used, in place of full-thickness specimens, each set shall represent a single tension test of the full pipe thickness. Closely, all of the specimens required to represent the full thickness of the weld at one location shall comprise a set.

(d) In the Reduced Section for the pipe, when multiple specimens are necessary, the entire thickness shall be mechanically cut into a minimum number (as per required) of approximately equal strips of a size that can be tested in the available testing equipment. Each and every specimen of the set shall be tested and meet the requirements of ASME SEC IX QW-153. For pipe having an outside diameter of 75 mm or less, reduced‐section specimens conforming to the requirements given in Figure QW-462.1(c) may be used for tension tests.

Bend test according to QW-150

SPECIMENS QW-161

Bend test specimens shall be prepared by the cutting test plate or pipe to form specimens of the approximately rectangular cross-section. The cut surface shall be designated on the sides of the specimens. The other two surfaces shall be called the face and root surfaces, the face surface having a greater width of welds. The specimen thickness and bend radius are shown in Figures QW-466.1, QW-466.2, and QW-466.3. Bend specimens are of five types, depending on whether the axis of the weld is transverse or parallel to the longitudinal axis of the specimens, and which surface (as a side, face, or root) is on the convex (outer) side of the bent specimen. The five types are as follows.

Transverse Side Bend.

The weld is transverse to the longitudinal axis of the specimen, which is bent so that one of the side surfaces becomes the convex of the surface of the bent specimen. Transverse side‐bend test specimens shall conform to the dimensions shown in Figure QW-462.2.

Specimens of base metal thickness equal to or greater than 38 mm may be cut into approximately equal strips between 19 mm and 38 mm wide for testing, or the specimens may be bent at full width. When the width of the weld is so large that a bent specimen cannot be bent so that the entire weld and heat affected zones are within the bent portion, multiple specimens across the entire weld and heat-affected zones shall be used.

If multiple specimens are used in either situation above, one complete set shall be made for each and every required test. Each specimen shall be tested and meet the requirement in QW-163.

Transverse Face Bend.

The test weld is transverse to the longitudinal axis of the specimens, which is bent so that the face of the surface becomes the convex surface of the bent specimens. Transverse face‐bend test specimens shall conform to the dimensions shown in Figure QW-462.3(a). For sub size transverse face bends, see QW-161.4.

|

| Longitudinal mechanical tests required for plate |

Transverse Root Bend.

The weld is transverse to the longitudinal axis of the specimen, which is bent so that the root of the surface becomes the convex surface of the bent specimens. Transverse root‐bend test specimens shall conform to the dimensions shown in Figure QW-462.3(a). For sub size transverse root bends, see QW-161.4.

Subsize Transverse Face and Root Bends.

Bend specimens were taken from small diameter pipe coupons maybe sub sized in accordance with General Note (b) of Figure QW-462.3(a).

Longitudinal-Bend Tests.

Longitudinal‐ bend tests may be used on behalf of the transverse side bend, face bend, and root‐bend tests for the testing weld metals or combinations of the base metal, which differ markedly in bending properties between (a) the two base metals, or (b) the weld metal and the base metal.

Longitudinal Face Bend.

The welds are parallel to the longitudinal axis of the specimen, which is bent so that the face surface becomes the convex surface of the bent specimens. Longitudinal face bend test specimens shall conform to the dimensions shown in ASME SEC-IX figure QW-462.3(b).

|

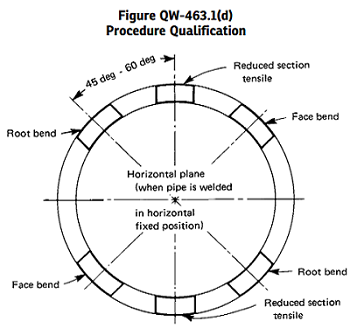

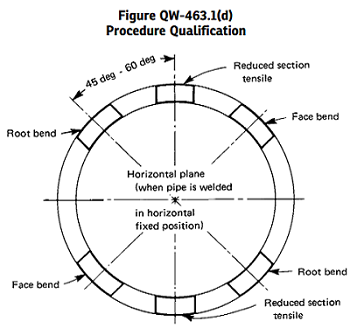

Procedure qualification test specimens

|

Longitudinal Root Bend.

In this longitudinal root bend, the weld is parallel to the longitudinal axis of the specimens, which is bent so that the root surface becomes the convex sides of the bent specimen. Longitudinal root‐bend test specimens shall conform to the dimensions shown in Figure ASME SEC-IX QW-462.3(b).

Acceptance criteria for tension tests according to QW-153

Tensile Strength.

Minimum values for procedure qualification record (PQR) are provided under the column heading “Minimum Specified Tensile strength, of the table QW/QB-422. In order to pass the tension test, the specimen shall have a tensile strength that is not less than;

(a) The minimum specified tensile strength of the base metals, or

(b) The minimum specified tensile strength of the weaker of the two if the base metals of different minimum tensile strengths are used, or

(c) The minimum specified tensile strength of the weld metal. when the applicable Section provides for the use of weld metal having lower room temperature strength than the base metal;

(d) If the specimen breaks into the base metal outside the weld or weld interface, the test shall be accepted when meeting the requirements, provided the strength is not more than 5 percent below the minimum specified tensile strength of the base metals.

(e) The specified minimum tensile strength is for full-thickness specimens including the cladding for Aluminum Alclad materials (as., P‐No. from 21 to 23) less than 13 mm. For Aluminum Alclad materials 13 mm and greater than the specified minimum tensile strength is for both full-thickness specimens that include cladding and specimens were taken from the core.

Acceptance criteria for Bend tests.

The weld and heat-affected zone of a transverse weld bend specimens shall be completely within the bent portion of the specimens after the testing. The bend specimens shall have not any open discontinuity in the weld or any heat-affected zone exceeding 3 mm, measuring in any direction on the convex surface of the specimens after bending of the test specimens. Open discontinuity occurring on the corners of the specimens during the testing shall not be considered unless there are definite shreds of evidence that results from the lack of fusions, slag inclusions, or and other internal discontinuities. For corrosion‐resistant weld overlay claddings, no open discontinuity exceeding 1.5 mm, measured in any direction, shall be permitted in the cladding, and no open discontinuity exceeding 3 mm shall be permitted along with the approximate weld interface.

Quick links for more details

WPS base metal qualification thickness range

Post a Comment

Please do not enter any spam link in the comment box.